SOLID STATE AMPLIFIERS 1, MOSFETS.

The contents of this page include :-

Brief note about my experience with solid state amps,

Picture of 2x300W amp.

Schematic of 300W AB amp channel with mosfets.

Schematic operation, topology, heatsinks, performance

specification,

NFB, thd, output current limiting, input voltage limiting, class A

operation.

Schematic of 600VA power supply for stereo 2 x 300W amp.

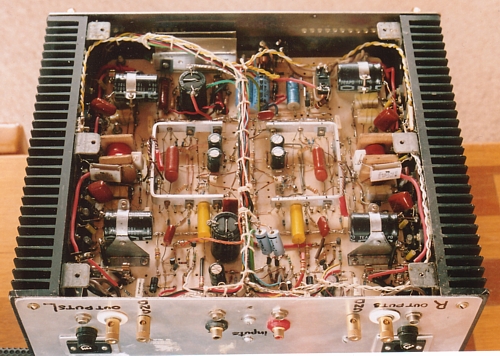

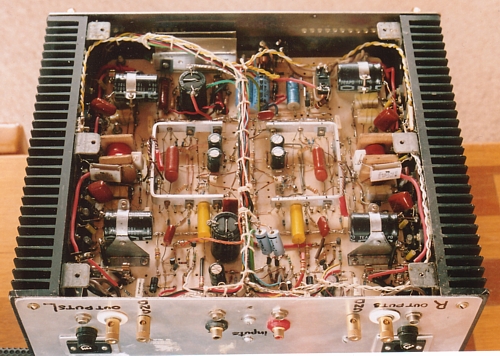

Picture of amp underside.

------------------------------------------------------------------------------------------

Although I try to specialize in tube amps, I have not always

avoided building

fine solid state amps and repairing them.

In 1993 I became seriously interested in all audio hi-fi

amplifiers at a time

when I thought I should change trades from construction work to

something

else.

My first project was upgrading a solid state Linear Design am/fm

receiver

I had bought in 1977 after I had forgotten how fine tube

amplifiers could be.

But later in 1993, I thought I should build a "better" dedicated

stereo amp.

I used two 100W mono amp kits designed by David Tilbrook who had

his

design published in ETI magazine in the 1980s. These kits were

available

in 1993 from a Jaycar outlet which had just set up a Canberra

store.

I very quickly learnt that the output mosfets and the input driver

transistors

were far easier to destroy than tubes by careless workshop

practices and

accidental short circuits.

After fusing a few transistors and mosfets I learnt to be very

careful with

everything I did. Direct coupled solid state amps with many PCB

tracks

close to each other are very prone to instant smoke with a

careless short

somewhere such as a splosh of solder, or from soldering two points

which are not meant to be soldered, or from tiny wire offcuts and

junk

sitting on soldered up boards. The speed of transistor failure is

that of

greased lightning, and unlike tube amp stages there is no R&C

coupling

which allows each stage to be more easily measured before anything

overheats to badly.

That first SS amp had 2 cascaded differential input stages instead

of just one.

Both used BF469/BF470 video transistors. The mosfet output stage

was in

source follower mode.

It was very easy to get excellent thd measurements, and the

circuit open loop

gain was so high that it could not be tested without the global

NFB connected.

It tended to be unstable above the AF band and in 1993 I was not

well skilled

about critical damping stabilization networks around a gain loop

where open

loop gain was extremely high which meant the amount of applied

global NFB

was also high.

The sound was no better than the sound I had enjoyed from my all

bjt Linear

Design receiver.

Following these efforts I read all the Wireless World and

Electronics World

magazine articles on audio from 1917 onwards.

The local Australian National University had all the old

magazines in their

basement archives.

Mr Tilbrook's design was abandoned because the second differential

gain stage

was simply not required to get thd and Rout low enough, ie, below

0.01% at

just under clipping, and Rout less than 0.05r. If the THD = 0.005%

at 100W,

then at 2W the THD was difficult to measure, ie, inaudible for

levels

used for most music.

I set about designing my own 100W per channel amp which

worked well with

just 3 input transistors in a differential pair with CCS, then a

single MJE340

gain transistor loaded by an MJE350 CCS followed by an NPN and PNP

power

mosfets. I found it very easy with such a simple circuit to get

100W at THD =

0.005%, and utterly negligible THD at 2W which covered all my

listening.

The build quality of that amp was too amateurish and wasn't

something I could

be entirely proud of so I dismantled it all and built a 2 x 300W

amp with

6 mosfets per channel.

2 x 300W amp with mosfets.

300W AMP WITH MOSFET OUTPUT STAGE.

Fig1, One 300w amp schematic of one channel.

There are six mosfets per channel in the output in complementary

source follower

mode.

The driver stage is also a complementary pair but with BF469/470

bjts in common

emitter mode for high gain. The collector load of each bjt is the

load for the other

of the pair and gain is very high in this simple driver stage.

There are two differential input stages, one npn and the other

pnp.

But they are not cascaded, but coupled to work in parallel to give

wide bandwidth,

low thd and symmetrical square wave performance to a high

frequency.

I found BF469 and BF470 were quite OK to use in the input and

driver stages.

Each of the aluminium extruded heatsinks for the flat pack mosfets

are 300mm long,

150mm high with 30 fins 40mm long, good for a 2 x 300W amp with no

need

for a fan even when left running at 300W into 4r0 with a sine

wave.

The total surface area of the heatsink is 30 x 15 x 4 x 2 = 3,600

square cm.

The required surface area needed to keep T rise less than 40C

approx is

about 40 sq.cm per W, so the extruded heatsinks I used are good

for 90W

of dissipation, or a lot more if one allows for a higher T rise.

If anyone follows my

simple rules here they should find their amps won't run hot, but

the heatsink fins

MUST be vertical, and not within a box which restricts air flow,

and causes rise.

Devices should be fixed to the heatsink with machine screws and

heat paste

and be spread over the area of the backing plate of the sink.

The 150mm x 300mm x 30 fin sink would be good for a 40W pure class

A amp which

needs to dissipate 90W at idle to allow 40W of class A.

I have thermal fuses fitted

to each heatsink to shut the amp down if the temperature exceeds

76C, but I have

never been able to trigger the fuse. I biased each channel it for

about 42W of idle

dissipation ( 300mA idle current ) which gives about 1.4W of class

A before moving

to class AB for the next 250W into 8 ohms. The high bias currents

in the mosfets stops

all tendencies of the mosfets to oscillate at RF where idle

currents are low, as used in

BJT amps.

The schematic is about as simple as a good 300W solid state amp

can be.

All the input driver bjts are mounted on a strip of aluminium

above the board to

keep them all at about the same temperature.

There is limiting of the input voltage to prevent excessive

accidental input voltage

being applied.

There is a decent protection circuit on the output used which

isn't shown, which

turns off the amp if there is a dc offset fault that exceeds about

+/- 1V for longer

than 4 seconds. The 0.5 ohm "N" source resistors are non magnetic

wire wound

types to prevent oscillations and force the mosfets to share the

the current evenly

and remain evenly biased without great need for the mosfets to be

accurately matched.

Anyone trying to build an amp with mosfet output devices should

anticipate parasitic

oscillations at RF. I found that 56pF from gate to drain with

short leads plus 560

ohm gate "stoppers" on each mosfet eliminated the RF oscillations.

I also have four

bypassing caps. The power supply has large 75V rated Sprague

100,000uF capacitors

on each +/- 70V rail, but the leads from the caps have enough

inductance to prevent

silent rails when testing with square waves so I placed 1,000 uF

electros + 0.47 uF

with short leads from the drain rails to 0V, then one 0.01uF from

each drain to the

chassis, and finally there was no more rail signal present at HF.

The open loop bandwidth is maximum at 200Hz but -3dB at about 5

kHz with only

180 ohms plus 100pF ( R23/C12 ) needed from the driver collectors

to bases of

Q7+Q8 to tailor the open loop phase and gain to stop overshoot and

HF instability.

In addition there is the C15 across R25, 47k to compensate for the

open loop phase

lag at HF. The RC zobel network R41+C28 from the commoned sources

to 0V act

to provide the amplifier with a resistive load above 100kHz when

the 0.22uF cap has

an impedance of 7.3 ohms. At F above 200kHz, the load on the

output stage is 10

ohms if there is not other load connected so the amp is more

likely to remain stable.

The value of C15 isn't given because in my case it was a pair of

short insulated

wires twisted together until the stability became excellent. A

trim cap of 3 to 20pF

could be used.

With 6r0 load, each mosfet sees 36r0 while in class A and then

18r0 when in class AB.

So while in class A the gain reduction in the output stage with

follower action is about

from 25 to about 1, and this local source follower series voltage

FB totals about 27dB.

The output stage works mainly in class AB and in fact not much

different to a class

B amp where there is no idle current at all. With no source

follower or global NFB

the THD of a pair of mosfets in complementary pair might be 10% at

250W to 8r0.

The 27dB of local NFB used in the source follower connection

reduces this to less than

1%. There is about 50dB of global NFB which means a total of 77dB

is operative.

The driver stage, Q7+Q8, has to produce a voltage slightly higher

than the speaker

output voltage and its open loop THD at about 45Vrms is about 3%

of which most is 3H

followed by 2H. This adds to the output stage THD to make a grand

total of about 4%

THD with no global NFB.

Most of the crossover distortion artefacts are reduced by the

local output stage NFB.

The 53dB of global FB reduces the 4% open loop THD by 53dB, or by

a factor of

0.00223, so 4% becomes 0.0089%, or just under 0.01%.

The THD is approximately proportional to the output voltage, and

at 4.5Vrms output

which is 2.5W / 8r0, THD < 0.001%, and rather difficult to

measure easily.

Such low THD is typical of many solid state amplifiers. However,

excellent THD, IMD

and TID measurements do not always tell the whole story about how

an amplifier will or

will not alter the sound signals than pass through it.

Tube amps with ten times the THD can sound better.

(( And by the way, anyone could operate the 300W amp design as a

pure class A

amp by having say 2 more output devices and dissipating about 80W

at idle,

and then using +/- 35Vdc rails instead of +/- 70Vdc. You could get

up to 36W pure class A,

depending on the load value. The same input stages and driver

stages would produce

about 3% open loop thd, and need some global NFB to reduce it. It

would not measure

much better than the above low bias class AB amp.

Subjectively, The class A operation of the output mosfets may

sound better than

having a 300W capability, which is never fully used. ))

With the class AB 300W amp as it is, any type of load can be

connected and an

8 uH inductance in parallel with 8 ohms protects the output stage

from over heating

if it ever had 5uF connected and the output signal had a high

level signal above 20kHz.

5uF is a difficult load, but there may be some electrostatics,

possibly made by

"Lartin Mogan", which present such an awkward load to an amp, but

usually all

awkward loads do have a series resistance in their equivalent

impedance

characteristic so that the worst of phase shifts and peak currents

at above 10kHz will

not bother the amplifier, and in any case the % of audio F energy

above 7 kHz is

usually very small. 5uF = 4.5 ohms at 7 kHz, and 2.27ohms at 14

kHz, and in fact

most amplifiers of any type will cope quite well with such a load

providing the

output voltage levels remains well below the maximum possible

which is probably

going to always be the case with an amp capable of 300W if it is

used for "normal hi-fi"

and with average speakers, which most ppl find sound loud enough

with never any

more than 10 W.

There could be a problem driving 5uF or with with insensitive

electrostatics if the

amplifier was only rated for 10W, and if high levels were wanted.

Quad ESL57 are

equivalent approximately to 1r6 in series with 2uF with 16r0

across the 1r6+2uF also

as a load. The response peaking effects caused by 2uF as the sole

load are usually

prevented by the series R in front of the C; the other 16r0

has little loading effect at all, and in fact ESL57 are very easy

loads to drive by

my 300W amp or any other amp. However, Quad's later model, the

Quad 63

and following models need more than a 20W amp.

There is current limiting that operates to prevent the output

stage from developing

excessive current which is dangerous to solid state devices which

can very rapidly

fail if the excessive current lasts for long enough to heat them

up and fuse the small

pn junction size of the active devices which are not much bigger

than a 4mm x 4mm

area.

Tubes have large metal areas

of perhaps 12sq.cm, ( EL34 ) and temporary adverse heat

dissipation can be

tolerated for longer than in a solid device.

The maximum theoretical peak load current = rail voltage / (

load + Ron + Rs )

where Ron is the minimum 'on' resistance of the mosfet when fully

turned on,

Rs = the source resistor. In this case if RL = 3r5, load on each

mosfet = 10r5,

Ron = 1r0 and Rs = 0.5r, so I max = 70V / 12r0 = 5.8Apk.

The rating for the mosfets is 7Apk.

The voltage gain of the mosfets reduces with RL value so a single

mosfet with

a 10r5 load plus Rs 0.5r will have a Vac change of 0V to +63.8Vpk,

and the Vg-s change needed is about +8V. There will be 2.9V across

the 0.5r Rs,

and the 9V zener diode plus other diode will conduct to prevent

any increase in

signal at the gates from over driving the mosfet.

To cut a long story short, in effect, the maximum current able to

be produced by the

amp = 14Apk for 3 mosfets, and in fact my measurements indicate

maximum load

current cannot be any higher than when load = 3r5 or lower, and

the output power

= 350W. So with 1r0 load there is still 14Apk peak produced, and

maximum output

power is about 100W.

The amplifier would become overheated with a load of 1r0 and

worked hard but

then the fuses in rails or at the output ( not shown ) would blow.

The amp is meant

to be used with loads above 4r0, but will tolerate normal home use

with loads down

to 2r0 where power is unlikely to average more than 3W per

channel, ever.

The only way to increase low impedance speaker load power handling

is to use

more of the same output devices or use devices with higher ratings

and more

of them on a bigger heatsink. Exicon flat pack mosfets rated for

16A each,

which would allow 40Vrms into 2r0 giving 800W.

I have never ever needed more than 50W for hi-fi at home.

There is an input voltage limiting circuit included which prevents

excessive input

voltages from being applied to the input transistors. Diodes D4

and D5 act to

shunt excessive input voltage just before the amp output stage

clips.

Below clipping the input limiters have zero action on the input

signal because each

diode which is a fast type with low forward turn on voltage

<0.25V is biased by

the resistance networks.

The input limiting may be omitted if really wish, but if used it

requires very

careful setting up to avoid any input clipping below high power

levels.

The amp has been reliable and trouble free and was a great

learning exercise to

build. I have surreptitiously substituted it for a 50W PP class A

tube amp during a

demonstration in about 1999, and the 3 other guys present did not

hear any noticeable

change. However, I had poorer speakers in those times using cheap

asian made drivers.

The speakers I have built since then use far better sounding SEAS

drive units and much

better enclosures and perhaps I now would not get away with

playing such skullduggery

on unsuspecting audiophiles.

Maximum output voltage is about 45Vrms. It is possible to use such

an amp in pure class A.

The bias Idc rail to rail may be increased to about 500mAdc, so

that about 70W may be

dissipated in each heatsink.

Using a toroidal audio transformer with 3 : 1 step down ratio, the

45Vrms is reduced to

15Vrms which will give 34W of pure class A into 6r6.

All power into loads above 6r6 will be pure class A.

There will be 75W class AB into 3r0 with initial 13W pure class

A.

A suitable toroidal is made by the man at www.zeroimpedance.com in

the USA.

When I wound the power transformer I used 4 x 25Vrms secondaries

all in series

to give 50V-0-50V which produces +/-70Vdc rails. The 25V rails

could be

paralleled to allow +/- 35V rails. The six mosfets could still

dissipate 70W but

be able to put 32W of pure class A into 16r0, 60W class AB into

8r0, including 16W

class A, 100W of class AB into 4r0 with 8W class A.

The measured distortion would become extremely low at audiophile

levels of power,

and perhaps the class A would convey some better subjective

fidelity.

People told me why my tube amps and mosfet amps both sound well.

One reason

is that they run warm without the devices being under stress and

do not run so hot

that devices will be short lived. My PP amps have always given

enough initial class A

power rather than hardly any at all. Friends were not able to tell

the difference between

my SS amps and tube amps in blind AB tests I did, and didn't mind

this because the

same guy was using similar philosophy for whatever he made.

One friend I had 4r0 Duntech Sovereign speakers which were huge

floor standing

units with many drivers. They could achieve astonishing sound

levels.

My friend played a vinyl

recording of 20 Africans beating away on drums and percussive

instruments thus generating a very "difficult" and transient rich

signal. We were able

to just get my 300W amp into clipping on the transients but the

outcome sounded

exactly like 20 Africans belting away furiously on leather and

wood. Of course such

levels could not be sustained or neighbours would call the police

control.

Some Lieder music from old Europe also sounded detailed and sweet,

and methinks

the 'Elephant' treads softly when required.

300W amp power supply.

Underside 2 x 300W amp.

Back to Index page